Color measurement of solid and powdered chemical products

Powdered chemicals are used in numerous industries such as the coatings, food, building materials, pharmaceuticals, plastics, cosmetics and detergents industries, to name but a few. Yellowness (Yellowness Index YI), whiteness (Whiteness Index WI), color fastness and also UV resistance, e.g. of pigments and fillers, flakes for paints, superabsorbents, granulates, resins and powder coatings are tested.

The world’s leading chemical manufacturers rely on HunterLab solutions to ensure the quality and consistency of finished products and raw materials throughout their supply chains with accurate and repeatable measurement results.

Our solutions for powders, minerals and fertilizers:

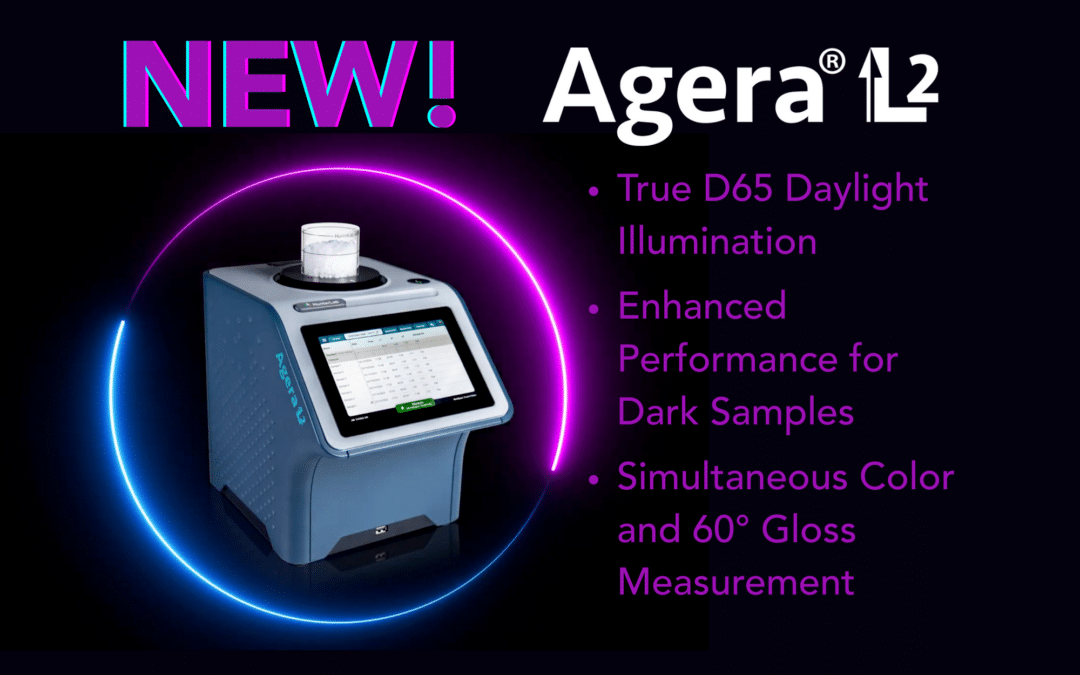

Agera L2

Color measurement “as the eye sees”

-

0°/45° geometry

This geometry according to DIN corresponds to the color impression that the human eye has of the sample.

-

Ultra dark mode

High-precision measurement values for deep black or low-light materials such as carbon black, black pigments and powders.

-

Improved QC software

The EasyMatch QC Essentials 2.0 quality control software is integrated into the device and offers all common color indices and color scales.

-

Full spectrum + UV

With an illumination range of 360-700 nm, the Agera is also suitable for measuring optically brightened samples. -

Smart user interface

Your measurement results can be easily transferred to existing LIMS or SPC systems.

-

Easy to use and precise

Simple "one touch" measurement reduces training time, optimizes the workflow and increases your productivity.

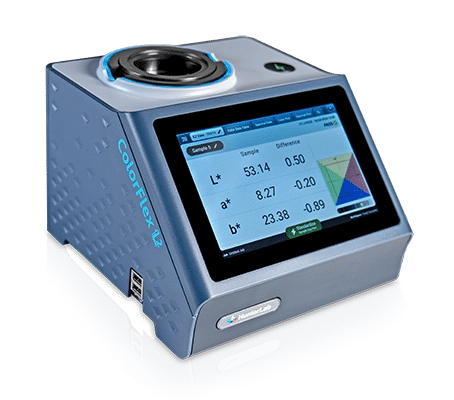

ColorFlex L2

Compact colorimetry station

-

Many different Port Plates

Many Port Plates (13 mm, 19 mm, 25.4 mm, 31.8 mm) for many types of samples.

-

Compact dimensions

With a weight of 2.75 kg and dimensions of 16 cm (height), 21 cm (width) and 24 cm (depth), the CFL2 is the ideal partner in the laboratory and production.

-

Integrated Essentials 2.0 QC software

Colour location visualization, spectral curves, spectral data and PASS/FAIL with individual tolerances.

-

45°/0° geometry

The CFL2 measures color as the human eye sees it. Every day. Reliable and precise.

-

In many versions

The ColorFlex L2 is also available in Tomato, Coffee and Citrus versions.

-

Easy to use and precise

Support from Help Wizard.

Reduces training time, optimizes the workflow and increases your productivity.

Application example:

Precise color measurement of chemical powders In the chemical industry, color is much more than just an optical feature - it is a decisive quality factor. With powders, catalysts and additives in particular, even a minimal color deviation can indicate differences in purity, composition or process control. Objective and reproducible color measurement therefore provides important information for quality assurance, product development and process control. Why color is so crucial in chemical powders Powdered chemicals are used in numerous applications - from pigments, fertilizers, binders and fillers to additives for plastics or coatings. Their color often provides information about: Purity...

Further information for you on this topic:

-

Agera brochure

-

ColorFlex L2 brochure

HunterLab worldwide:

-

Europe / Middle East / Africa

HunterLab Europe GmbH

-

Dr.-August-Einsele-Ring 15

82418 Murnau

-

+49 8841 9464

Your local partner:

-

Headquarters, North / South America

Hunter Associates Laboratory, Inc.

-

11491 Sunset Hills Road

Reston, VA 20190-5280

-

+1 571 470 6028

-

Asia-Pacific

HunterLab Asia Limited -

Flat E, 13F Leahander Center,

28 Wang Wo Tsai Street,

Tsuen Wan,

New Territories,

Hong Kong -

+852 2406 1723

Ask us your question here...

Would you like to talk directly about your application/sample? Give us a call at

We will show you the colour measurement solution for your product.

Or simply fill out the form below.

Our colorimetry experts will be happy to help you!

The blog of HunterLab Europe

Everything to do with color measurement

In the plastics, chemical and recycling industries, color is much more than just an optical feature. It is a key quality indicator that allows conclusions to be drawn about material purity, process stability and batch consistency. In granulate production in particular, the smallest color deviations can have enormous economic consequences - especially if they are detected too late. Inline color control = zero waste A large plastics compounder and recycling specialist in Germany faced precisely...

HunterLab at Europe's trade fairs 2026 - Dates, locations and highlights There is no...

New Product Innovation from HunterLab - The Agera L2 The demands placed on industrial colour...