Precise colour measurement of chemical powders

In the chemical industry, colour is far more than a visual attribute – it is a crucial indicator of quality.

Especially for powders, catalysts, and additives, even the slightest colour deviation can point to differences in purity, composition, or process conditions.

Objective and repeatable colour measurement therefore provides valuable insights for quality assurance, product development, and process control.

Why Colour Matters in Chemical Powders

Powdered chemicals are used in a wide range of applications – from pigments, fertilisers, binders, and fillers to additives for plastics and coatings. Their colour often provides information about:

-

Purity and particle morphology

-

Reaction degree and temperature control during synthesis

-

Stability or ageing due to storage or light exposure

-

Homogeneity and batch consistency

In quality control, colour measurement is a fast and reliable method that delivers objective data – independent of visual perception or ambient lighting conditions.

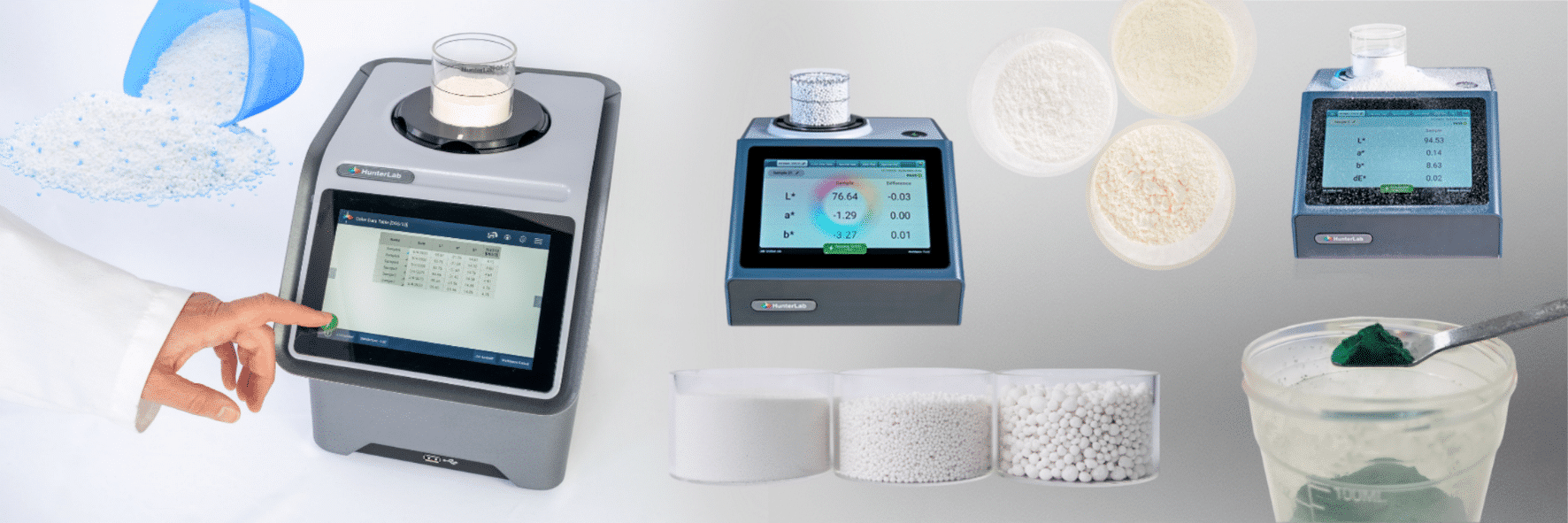

ColorFlex L2 – The Simple Solution for Powder Measurements in Laboratory or Production

The new ColorFlex L2 spectrophotometer is ideally suited for the colour measurement of chemical powders, granulates, and additives.

With its 45°/0° measurement geometry, it measures colour exactly as the human eye perceives it – making it perfect for products that were previously evaluated visually.

Practical advantages:

✅ Easy sample handling – powders can be measured directly in dishes or Petri dishes

✅ Precise and repeatable results

✅ Quick calibration and intuitive Essentials 2.0 software

✅ Robust and compact – ideal for both laboratory and production environments

This allows colour deviations between production batches to be detected, documented, and corrected before they affect the final product.

Agera – for UV-active substances and whiteness measurements

If powders contain optically active or fluorescent components, or if the degree of whiteness (e.g. for catalysts, fillers or titanium dioxide-based additives) needs to be determined, the Agera spectrophotometer is the right choice.

If powders contain optically active or fluorescent components, or if the degree of whiteness (e.g. for catalysts, fillers or titanium dioxide-based additives) needs to be determined, the Agera spectrophotometer is the right choice.

With its 0°/45° measuring geometry and UV calibration, the Agera enables precise measurement even with materials that fluoresce under UV light. The integrated camera supports optimum sample positioning.

Typical applications:

- UV-active additives in polymer formulations

- White pigments or catalysts containing optical brighteners

- Universally applicable, whether powder, agglomerate or pellets

FAQ

How are chemical powders measured?

Powders are usually measured in glass round cuvettes or plastic Petri dishes. The spectrophotometer illuminates the sample at a defined angle and records the reflected light. This produces objective color values in the CIE L*a*b* color space or as a color index (e.g., WI, YI, 457 brightness, Ganz/Griesser, among others).

What influences the measurement results?

Particle size, density, and scattering properties can slightly alter the measured color. Therefore, standardized sample preparation and a uniform surface are important.

Can fluorescent or UV-active powders be measured?

Yes – Instruments like the HunterLab Agera can be used to identify optically brightened samples. It has an illumination range of 360-700 nm and a spectral range of 400-700 nm. For measurements of optically brightened samples, the device has a software-controlled UV option. In addition to a complete UV exclusion, the UV component can also be calibrated.

Which software is suitable for evaluating chemical powders?

The integrated QC software Essentials 2.0 includes all the necessary color data, trend plots, and views. For further data processing, both the ColorFlex L2 and the Agera can be integrated into existing LIMS/SPC systems.

Conclusion

Colour measurement of chemical powder substances has become an essential part of modern quality control.

With the ColorFlex L2 for routine testing and the Agera for advanced applications involving UV activity or whiteness evaluation, laboratories and production environments gain two perfectly complementary solutions.

Both systems stand for precision, reliability, and user-friendliness – made by HunterLab.

HunterLab: Your partner for precise color measurement

HunterLab is the world’s leading manufacturer of spectrophotometers for measuring the color of food and beverages. Our innovative solutions have ensured outstanding color quality in many industries for over 70 years. Renowned corporations and companies around the world rely on our devices and customer-oriented service. With 14 agencies throughout Europe and a dedicated team in the European HunterLab office, we support users with all colorimetric issues.

Talk to our colorimetry experts to get a quote or advice.